Welp... not going to finish today.

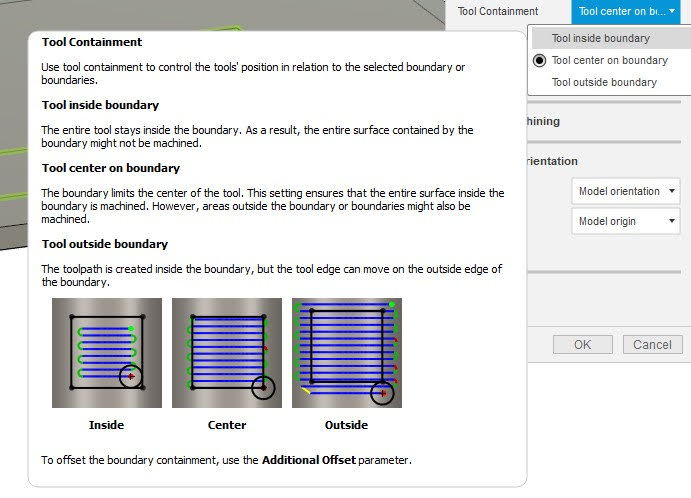

One of the sockets broke on me and I cut the project top too big. I thought I was being slick with my CNC and selected the wrong "tool containment" so everything was about 3mm too big.

Cut this power socket by hand, it's very rough but thankfully there's enough overlap to make it look good from the outside.

Broken Power Plug, first "squeeze" and the two flaps just broke off:

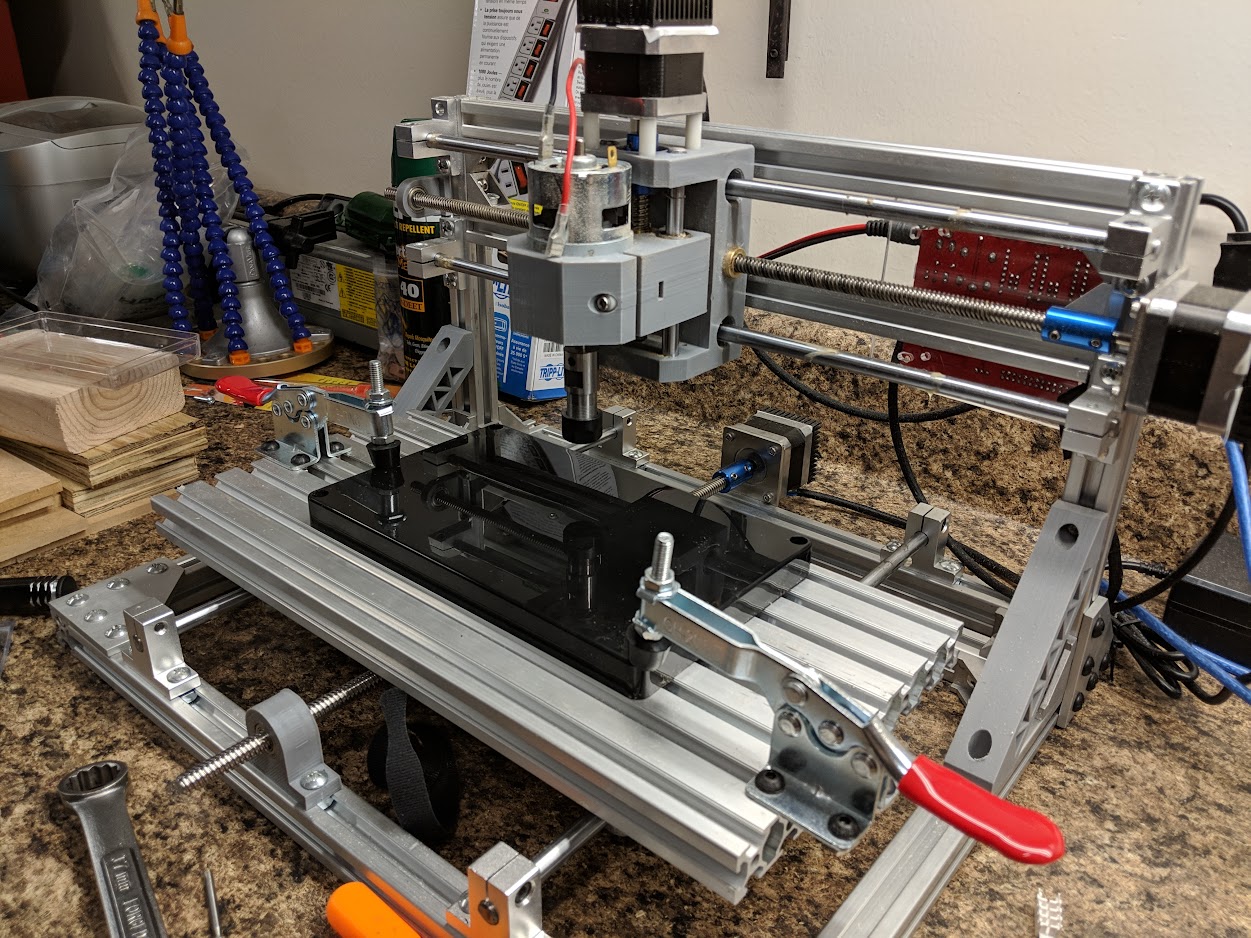

CNC doing a test path (making sure there wasn't going to be any collisions. :

What the finished should look like:

Reality is those are barely hanging in there. If they move too much in any direction they "could" fall through. I'm not going to risk that... Plus I spaced them too much I think. I want to move them more to one side so that I could fit the relay on the top easier.

Back to Amazon... that was a $12 mistake with the project box.

This is where I messed up, I left it at Center when I meant for it to be "inside" containment.... I changed it earlier but went back and modified something and didn't change this.

One of the sockets broke on me and I cut the project top too big. I thought I was being slick with my CNC and selected the wrong "tool containment" so everything was about 3mm too big.

Cut this power socket by hand, it's very rough but thankfully there's enough overlap to make it look good from the outside.

Broken Power Plug, first "squeeze" and the two flaps just broke off:

CNC doing a test path (making sure there wasn't going to be any collisions. :

What the finished should look like:

Reality is those are barely hanging in there. If they move too much in any direction they "could" fall through. I'm not going to risk that... Plus I spaced them too much I think. I want to move them more to one side so that I could fit the relay on the top easier.

Back to Amazon... that was a $12 mistake with the project box.

This is where I messed up, I left it at Center when I meant for it to be "inside" containment.... I changed it earlier but went back and modified something and didn't change this.

Last edited: