Cody

Vice President

Staff member

Administrator

Moderator

Content Moderator

Board Member

Supporting Member

Dude, put on a shirt. No one wants to see your nipples....except me.

Dude, put on a shirt. No one wants to see your nipples....except me.

Interesting. I have not heard that hypothesis before.I believe the general consensus is not to mix bacterial additives.

Each product could be a different strain and they could end up competing with each other and perhaps slowing down your insta cycle.

I love this idea!I have a 60” aquatic life T5 fixture and 3 RS Reefled 90 in the center. The way everything sits, it casts off a ton of glare and spillage. I was searching for a lightweight and easy to work with material for a light skirt. After some back and forth, I decided on polyurethane(?) crown molding.

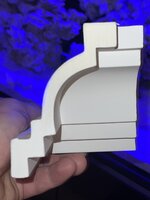

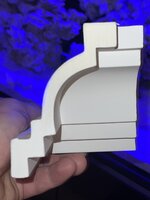

The profile looked like this..

The whole frame slides on the aquatic life fixture and sits on the first ledge from the top. I do not have a miter box saw so I just bought the preformed corners and glued the straights.

I taped up the joints from the inside (underside) with masking tape and used original gorilla glue. The process is to wet the surface and then apply the glue. I was able to use syringes for both parts, squirted water in the joints and filled them with gorilla glue. The glue expands and foams into an easy to work with material that can be sanded and painted. Once the initial frame is glued together and sanded down, fill all remaining imperfections with joint compound. Sand once more and spray paint.