G

Guest

NATURAL DIATOM ALGAE CONTROL FOR REEF AQUARIUMS

Geothermal Aquaculture Research Lab

--------------------------------------------------------------------------------

REEF ALGAE CONTROL CENTRAL

IF YOUR REEF AQUARIUM IS LESS THAN FOUR MONTHS OLD AND THE MAIN PROBLEM ALGAE IS A LIGHT RED BROWN DUSTING ON THE GLASS AND ROCKS - YOUR REEF HAS A DIATOM BLOOM. The Reef janitors Diatom control mixture contains extra Cerith and Nerite snails. Both of these Janitors do a great job of eating Diatom algae.

--------------------------------------------------------------------------------

INDEX

REEF AQUARIUM JANITOR ORDER FORM

LIVE SAND ACTIVATOR

REEF JANITOR SPECIAL SALE

GREAT REEF AQUARIUM LINKS

--------------------------------------------------------------------------------

CERITH SNAIL

Family Cerithiidae (CERITHS)

Cerithium strercusmuscarum

NEW - THIS SNAIL EATS DIATOM ALGAE -

Dark brown sculptured tower shaped (Turriform) algae eater. Active glass cleaner

This is the best cerith snail we have tested. It stays down in the aquarium on the glass cleaning algae and diatoms. It is listed in Julian Sprung's Reef Aquarium as a good algae eater. One inch long pointed shell, it can get in between rocks, it is a great glass cleaner. This snail cleans in zig zag pattern. It's radula is able to remove diatoms so well that they do not regrow from the original algal film. This snail does not dislodge or disturb any specimens.

SUGGESTED RETAIL EACH $2.98

--------------------------------------------------------------------------------

NERITE SNAIL

Family Neritidae

Nerita funiculata

Brown and black round algae eater. Active glass cleaner This species of Mexican Nerite is the best one we have tested. IT STAYS IN AQUARIUM

This snail lives much longer than astraea, it is slower and much better at removing all the algae and diatoms from the rocks and glass. This snail does not leave an algae film on the glass. It is also listed in Julian Sprung's Reef Aquarium as a good algae eater.

One half inch round shell with ridges. Found only on smooth rocks below average lowest tide. The choice of reef expert Larry Read.

SUGGESTED RETAIL EACH $2.98

REEF AQUARIUM JANITOR ORDER FORM

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

LIVE SAND ACTIVATOR

DIATOMS ARE OFTEN A PROBLEM IN NEW TANKS BECAUSE THEY DO NOT CONTAIN THE MICRO ANIMALS THAT EAT DIATOMS. THIS GRUNGE WILL ADD MANY OF NEEDED MICRO GRAZERS YOUR REEF AQUARIUM LACKS.

CONTROL DIATOMS WITH GARF GRUNGE*

BACTERIA AND OTHER ORGANISMS FROM THE FINEST MARINE AQUARIUMS THAT WE HAVE KEPT DURING THE LAST TWENTY YEARS. WE ADD TO THIS GENETIC POOL OF FILTER ANIMALS EACH TIME WE RECEIVE LIVE ROCK FOR OUR RESEARCH.

GARF GRUNGE* HAS A VERY LARGE NUMBER OF CORALINE ALGAE SPECIES IN IT.

NO WILD LIVE SAND CAN HAVE THE BIODIVERSITY FOUND IN THIS ACTIVATOR!

$5.00 PER POUND

Reef aquariums require a large variety of organisms to filter the water properly. Aquarium habitat is very different from ocean habitat.

Live Sand from a natural reef is good for starting marine aquariums, but each location on a reef has a limited number of species. Poor packing and shipping methods further deplete this fragile wild population.

We have been keeping an unbroken chain of successful reef aquariums in Idaho since 1977. Several times during this period we have had over 100 aquariums. We have researched captive breeding of such diverse species as Chambered Nautilus and Acropora coral.

LIVE ROCK RESEARCH

Our continuing research into the commercial production of tank raised live rock has allowed us to purchase tons of prime live rock and live sand. We select species from the rock for our live rock genetic bank.

During the last year I was able to purchase over 1000 lbs. of the live sand and rubble from the bottom of the live rock holding tanks at several of the most famous live rockers.

This mixture was much more than just live sand!! Hundreds of invertebrates from the tons of live rock held in these tanks are now reproducing here in Idaho.

RESEARCH COLLECTING TRIPS

This mixture is now being added to by myself and Sally Jo. We are collecting sand stirrers and filter organisms on our research trips. We have made several trips to Mexico during the last two years looking for a site for a live rock farm. We are able to select various types of live sand for our experiments.

Last year Tom Frakes and I Explored Coronado Island in the Sea of Cortez. We found a bay with sand made up of branching coraline algae fragments. This coraline is the fastest growing dark purple and blue types I have found.

TRY LIVE SAND ACTIVATOR

GARF GRUNGE $5.00 LB.

0NE POUND FOR EACH THREE GALLONS WILL ACTIVATE TWO INCHES OF ARAGONITE SAND

ADD ONE POUND PER 10 GALLONS TO IMPROVE WILD LIVE SAND!

³the most important part. This is a "Grunge" from G.A.R.F. What the stuff contains is a culture of sand, coral rubble, small reef rocks, macro-algae, annelid worms, small pieces of sponges and corals, snails and crabs that is some of the coolest stuff I have ever seen!

I still keep seeing different things I didn't see before. We got 10 pounds about a week after the system was set up and mixed it in with the top layer of sand. This really gave the reef a pleasing natural look since it is very coarse and has a lot of color to it² *

Letter from The Sea Star

A monthly publication

for the marine aquarium hobbyist

by the President - Tim L. Weidauer

Wasatch Marine Society in Salt Lake City, UT.

--------------------------------------------------------------------------------

HOW TO ORDER DIATOM CONTROLREEF JANITOR MIXTURE*

JANITOR SPECIAL SALE

WE ARE OFFERING THIS COMPLETE REEF JANITOR PACKAGE FOR $1.50 PER GALLON.

WHEN YOU PURCHASE OUR JANITOR MIXTURE YOU SAVE 2/3 OF YOUR MONEY AND YOU WILL HAVE THE PROPER MIXTURE OF HERMIT CRABS AND SNAILS TO KEEP YOUR REEF ALGAE FREE

REEF AQUARIUM JANITOR ORDER FORM

--------------------------------------------------------------------------------

REEF DIATOM ALGAE REEF JANITOR SPECIAL ORDER FORM

PLEASE SEND ME

Red Leg Hermit Crabs for -- $2.98 each, plus shipping and handling

Diatom algae eating snails for -- $2.98 each, plus shipping and handling

live sand activator for -- $5.00 per lb., plus shipping and handling

30 GALLON REEF Forty five diatom control reef janitors for only $1.00 each.

ÝÝÝÝ -- $45.00, plus shipping and handling

50 GALLON REEF Eighty two diatom control reef janitors for only $1.00 each

ÝÝÝÝ -- $82.00, plus shipping and handling

100 GALLON REEF One hundred fifty diatom control reef janitors for only $1.00 each.

ÝÝÝÝ -- $150.00, plus shipping and handling

For us to fill your order, please enter your name, E-mail and phone numbers and we will call you to take down the size of your aquarium so we can help you order the proper mixture of reef janitors and Garf Grunge. We will ask for your mailing address and payment information. Thank you!! Alternatively, you may also print out and either mail or fax your order to 208-344-6189

--------------------------------------------------------------------------------

MISSION STATEMENT

TO PROVIDE THE CITIZENS OF IDAHO AND THE WORLD A SHOWCASE COLLECTION OF AQUATIC PLANTS, FISH, REEF ANIMALS AND PRODUCTS. TO STIMULATE INTEREST IN, APPRECIATION FOR AND AN UNDERSTANDING OF THESE COLLECTIONS. TO BE IMPLEMENTED THROUGH PLANT RECORDS, PUBLIC DISPLAYS, COLLECTIONS, APPLIED RESEARCH, PUBLICATIONS, INTERNSHIP PROGRAMS, AND SALES OF QUALITY PRODUCTS.

--------------------------------------------------------------------------------

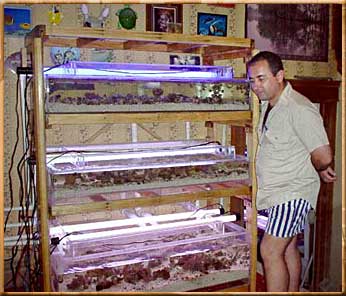

Much of our research is being conducted in the field of reef farming. We are conducting these studies both in marine aquariums and in the ocean. Reef aquarium research is being conducted by members of the foundation both in the U.S. and in several other countries.

We also supply expert advice on algae control for the reef aquarium, wetlands and backyard ponds.

GREAT REEF AQUARIUM LINKS

Super glue research page Learn the newest method of invertebrate propagation

Super Glue evaluaton page Our researchers rate many brands of super glue

Geothermal Aquculture Research Foundation Feed Back page Please E-mail input so we can make these pages better

Soft Coral Propagation Page Pictures and details of soft coral propagation

Stony Coral Propagation Page Pictures

Learn to construct a 140 gallon plywood amd epoxy reef tank

--------------------------------------------------------------------------------

Contact: LeRoy Headlee - Sally Jo Headlee | Phone: 208-344-6163 | Fax: 208-344-6189

--------------------------------------------------------------------------------

Email: leroy@garf.org

--------------------------------------------------------------------------------

Geothermal Aquaculture Research Lab

--------------------------------------------------------------------------------

REEF ALGAE CONTROL CENTRAL

IF YOUR REEF AQUARIUM IS LESS THAN FOUR MONTHS OLD AND THE MAIN PROBLEM ALGAE IS A LIGHT RED BROWN DUSTING ON THE GLASS AND ROCKS - YOUR REEF HAS A DIATOM BLOOM. The Reef janitors Diatom control mixture contains extra Cerith and Nerite snails. Both of these Janitors do a great job of eating Diatom algae.

--------------------------------------------------------------------------------

INDEX

REEF AQUARIUM JANITOR ORDER FORM

LIVE SAND ACTIVATOR

REEF JANITOR SPECIAL SALE

GREAT REEF AQUARIUM LINKS

--------------------------------------------------------------------------------

CERITH SNAIL

Family Cerithiidae (CERITHS)

Cerithium strercusmuscarum

NEW - THIS SNAIL EATS DIATOM ALGAE -

Dark brown sculptured tower shaped (Turriform) algae eater. Active glass cleaner

This is the best cerith snail we have tested. It stays down in the aquarium on the glass cleaning algae and diatoms. It is listed in Julian Sprung's Reef Aquarium as a good algae eater. One inch long pointed shell, it can get in between rocks, it is a great glass cleaner. This snail cleans in zig zag pattern. It's radula is able to remove diatoms so well that they do not regrow from the original algal film. This snail does not dislodge or disturb any specimens.

SUGGESTED RETAIL EACH $2.98

--------------------------------------------------------------------------------

NERITE SNAIL

Family Neritidae

Nerita funiculata

Brown and black round algae eater. Active glass cleaner This species of Mexican Nerite is the best one we have tested. IT STAYS IN AQUARIUM

This snail lives much longer than astraea, it is slower and much better at removing all the algae and diatoms from the rocks and glass. This snail does not leave an algae film on the glass. It is also listed in Julian Sprung's Reef Aquarium as a good algae eater.

One half inch round shell with ridges. Found only on smooth rocks below average lowest tide. The choice of reef expert Larry Read.

SUGGESTED RETAIL EACH $2.98

REEF AQUARIUM JANITOR ORDER FORM

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

LIVE SAND ACTIVATOR

DIATOMS ARE OFTEN A PROBLEM IN NEW TANKS BECAUSE THEY DO NOT CONTAIN THE MICRO ANIMALS THAT EAT DIATOMS. THIS GRUNGE WILL ADD MANY OF NEEDED MICRO GRAZERS YOUR REEF AQUARIUM LACKS.

CONTROL DIATOMS WITH GARF GRUNGE*

BACTERIA AND OTHER ORGANISMS FROM THE FINEST MARINE AQUARIUMS THAT WE HAVE KEPT DURING THE LAST TWENTY YEARS. WE ADD TO THIS GENETIC POOL OF FILTER ANIMALS EACH TIME WE RECEIVE LIVE ROCK FOR OUR RESEARCH.

GARF GRUNGE* HAS A VERY LARGE NUMBER OF CORALINE ALGAE SPECIES IN IT.

NO WILD LIVE SAND CAN HAVE THE BIODIVERSITY FOUND IN THIS ACTIVATOR!

$5.00 PER POUND

Reef aquariums require a large variety of organisms to filter the water properly. Aquarium habitat is very different from ocean habitat.

Live Sand from a natural reef is good for starting marine aquariums, but each location on a reef has a limited number of species. Poor packing and shipping methods further deplete this fragile wild population.

We have been keeping an unbroken chain of successful reef aquariums in Idaho since 1977. Several times during this period we have had over 100 aquariums. We have researched captive breeding of such diverse species as Chambered Nautilus and Acropora coral.

LIVE ROCK RESEARCH

Our continuing research into the commercial production of tank raised live rock has allowed us to purchase tons of prime live rock and live sand. We select species from the rock for our live rock genetic bank.

During the last year I was able to purchase over 1000 lbs. of the live sand and rubble from the bottom of the live rock holding tanks at several of the most famous live rockers.

This mixture was much more than just live sand!! Hundreds of invertebrates from the tons of live rock held in these tanks are now reproducing here in Idaho.

RESEARCH COLLECTING TRIPS

This mixture is now being added to by myself and Sally Jo. We are collecting sand stirrers and filter organisms on our research trips. We have made several trips to Mexico during the last two years looking for a site for a live rock farm. We are able to select various types of live sand for our experiments.

Last year Tom Frakes and I Explored Coronado Island in the Sea of Cortez. We found a bay with sand made up of branching coraline algae fragments. This coraline is the fastest growing dark purple and blue types I have found.

TRY LIVE SAND ACTIVATOR

GARF GRUNGE $5.00 LB.

0NE POUND FOR EACH THREE GALLONS WILL ACTIVATE TWO INCHES OF ARAGONITE SAND

ADD ONE POUND PER 10 GALLONS TO IMPROVE WILD LIVE SAND!

³the most important part. This is a "Grunge" from G.A.R.F. What the stuff contains is a culture of sand, coral rubble, small reef rocks, macro-algae, annelid worms, small pieces of sponges and corals, snails and crabs that is some of the coolest stuff I have ever seen!

I still keep seeing different things I didn't see before. We got 10 pounds about a week after the system was set up and mixed it in with the top layer of sand. This really gave the reef a pleasing natural look since it is very coarse and has a lot of color to it² *

Letter from The Sea Star

A monthly publication

for the marine aquarium hobbyist

by the President - Tim L. Weidauer

Wasatch Marine Society in Salt Lake City, UT.

--------------------------------------------------------------------------------

HOW TO ORDER DIATOM CONTROLREEF JANITOR MIXTURE*

JANITOR SPECIAL SALE

WE ARE OFFERING THIS COMPLETE REEF JANITOR PACKAGE FOR $1.50 PER GALLON.

WHEN YOU PURCHASE OUR JANITOR MIXTURE YOU SAVE 2/3 OF YOUR MONEY AND YOU WILL HAVE THE PROPER MIXTURE OF HERMIT CRABS AND SNAILS TO KEEP YOUR REEF ALGAE FREE

REEF AQUARIUM JANITOR ORDER FORM

--------------------------------------------------------------------------------

REEF DIATOM ALGAE REEF JANITOR SPECIAL ORDER FORM

PLEASE SEND ME

Red Leg Hermit Crabs for -- $2.98 each, plus shipping and handling

Diatom algae eating snails for -- $2.98 each, plus shipping and handling

live sand activator for -- $5.00 per lb., plus shipping and handling

30 GALLON REEF Forty five diatom control reef janitors for only $1.00 each.

ÝÝÝÝ -- $45.00, plus shipping and handling

50 GALLON REEF Eighty two diatom control reef janitors for only $1.00 each

ÝÝÝÝ -- $82.00, plus shipping and handling

100 GALLON REEF One hundred fifty diatom control reef janitors for only $1.00 each.

ÝÝÝÝ -- $150.00, plus shipping and handling

For us to fill your order, please enter your name, E-mail and phone numbers and we will call you to take down the size of your aquarium so we can help you order the proper mixture of reef janitors and Garf Grunge. We will ask for your mailing address and payment information. Thank you!! Alternatively, you may also print out and either mail or fax your order to 208-344-6189

--------------------------------------------------------------------------------

MISSION STATEMENT

TO PROVIDE THE CITIZENS OF IDAHO AND THE WORLD A SHOWCASE COLLECTION OF AQUATIC PLANTS, FISH, REEF ANIMALS AND PRODUCTS. TO STIMULATE INTEREST IN, APPRECIATION FOR AND AN UNDERSTANDING OF THESE COLLECTIONS. TO BE IMPLEMENTED THROUGH PLANT RECORDS, PUBLIC DISPLAYS, COLLECTIONS, APPLIED RESEARCH, PUBLICATIONS, INTERNSHIP PROGRAMS, AND SALES OF QUALITY PRODUCTS.

--------------------------------------------------------------------------------

Much of our research is being conducted in the field of reef farming. We are conducting these studies both in marine aquariums and in the ocean. Reef aquarium research is being conducted by members of the foundation both in the U.S. and in several other countries.

We also supply expert advice on algae control for the reef aquarium, wetlands and backyard ponds.

GREAT REEF AQUARIUM LINKS

Super glue research page Learn the newest method of invertebrate propagation

Super Glue evaluaton page Our researchers rate many brands of super glue

Geothermal Aquculture Research Foundation Feed Back page Please E-mail input so we can make these pages better

Soft Coral Propagation Page Pictures and details of soft coral propagation

Stony Coral Propagation Page Pictures

Learn to construct a 140 gallon plywood amd epoxy reef tank

--------------------------------------------------------------------------------

Contact: LeRoy Headlee - Sally Jo Headlee | Phone: 208-344-6163 | Fax: 208-344-6189

--------------------------------------------------------------------------------

Email: leroy@garf.org

--------------------------------------------------------------------------------