In short the issue I have is my return plumbing is vinyl tubing. I seems to keep shrinking, with use of saltwater, thus cutting off the flow.

I have a DC pump that can put out up to 1500 gph at 4 ft head pressure, but with 3/4 inch tubing the max output is just under 700 gph. The problem is the vinyl tubing shrinks to under 5/8 over time, 6 months, so I am now getting under 400 gph in a 90 gallon DT with an added 35 gallons in the sump.

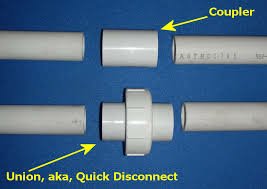

I wanted to increase the return to at least the original 3/4 but increase if I could. I found out that the overflow bulkheads can increase to 1 1/4 inches. So I will be increasing both return and drain to 1 1/4". This should give me more than enough flow. I will be using Spa Flex (flexible PVC) to solve the shrinking problem. I will also put a ball valve to help control the flow amount. I also plan on diverting a little flow back into the sump to agitate the dead spots in the sump.

If my calculations are correct this will increase my flow up to 1100 gph, more than enough. I will not need that much turnover. Actually that would be way too much turnover, but I like the ability to have options.

Pics will follow when I start

Steps

Cut Access. (Hard Part)

Clean out overflow.

Dismantle drain and return.

Change bulkheads.

Run and form SpaFlex. (Very Hard part)

Plumb the ball valves, splitter and homemade spray bar.

Adjust settings.

Pour Bourbon & Coke and enjoy.

Let me know if I missed anything?

I have a DC pump that can put out up to 1500 gph at 4 ft head pressure, but with 3/4 inch tubing the max output is just under 700 gph. The problem is the vinyl tubing shrinks to under 5/8 over time, 6 months, so I am now getting under 400 gph in a 90 gallon DT with an added 35 gallons in the sump.

I wanted to increase the return to at least the original 3/4 but increase if I could. I found out that the overflow bulkheads can increase to 1 1/4 inches. So I will be increasing both return and drain to 1 1/4". This should give me more than enough flow. I will be using Spa Flex (flexible PVC) to solve the shrinking problem. I will also put a ball valve to help control the flow amount. I also plan on diverting a little flow back into the sump to agitate the dead spots in the sump.

If my calculations are correct this will increase my flow up to 1100 gph, more than enough. I will not need that much turnover. Actually that would be way too much turnover, but I like the ability to have options.

Pics will follow when I start

Steps

Cut Access. (Hard Part)

Clean out overflow.

Dismantle drain and return.

Change bulkheads.

Run and form SpaFlex. (Very Hard part)

Plumb the ball valves, splitter and homemade spray bar.

Adjust settings.

Pour Bourbon & Coke and enjoy.

Let me know if I missed anything?